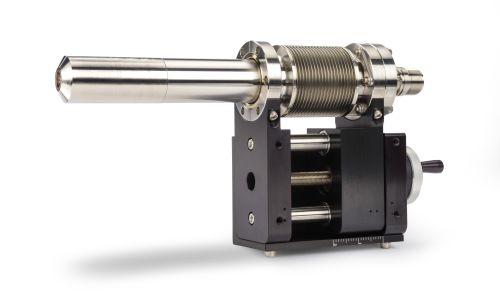

Includes cylindrical mirror analyzer, USB controller and Windows acquisition and data massage software.

Simple to operate and easy to maintain, the microCMA provides a quantitative surface-sensitive AES Auger Electron Spectroscopy analyzer package that mounts on a 2.75”/ 70 mm CF flange.

For elemental analysis, the microCMA is much more affordable than a standalone XPS system.

The complete AES system includes the cylindrical mirror analyzer (with integrated coaxial electron source), a USB interface controller, and Windows acquisition and data-massage software. It's Auger analysis made easy!

Base package: microCMA analyzer, USB interface controller, preamp with 15 ft (4.6m) cable, data acquisition and massage software, and manual.

Optional accessories: XYZ translator, 9103 USB picoammeter, custom lengths for CMA and preamp cable.

Complete configuration and ordering information...

We at RBD Instruments think that the microCMA is the best little AES cylindrical mirror analyzer on the planet.

By utilizing the cylindrical mirror design, the microCMA has the same sensitivity and energy resolution as much larger and more expensive Auger Electron spectrometers.

A CMA accepts electrons at a 42.3° angle (which is the angle where second-order focusing is possible). The CMA Entrance Angle drawing shows that both the 2.75" flange microCMA and the 10.0" 25-120A CMA (used on the PHI 660 system) accept electrons at the 42.3° angle. Since the microCMA has a smaller diameter than the 25-120A, the end of optics-to-sample distance is shorter. But the same electrons are collected whether using the microCMA or the 25-120A.

CMA Entrance Angle

As shown in the two surveys below, the Auger data taken by the microCMA and 25-120A full-size analyzer are comparable. The surveys are copper samples which were both acquired with 3kV electron beam energy and 300nA of target current.

microCMA Compact Auger Analyzer

25-120A Full-size Auger Analyzer (PHI 660 System)

The microCMA is an Auger Spectroscopy cylindrical mirror analyzer designed for the many applications for Auger analysis that do not require AES mapping capability

Those applications include analysis of:

Learn more about Auger Spectroscopy

Learn about using Auger for Molecular Beam Epitaxy (MBE)

Overview Video

Not sure if the microCMA can meet your needs? Send us a sample for analysis.

Contact us for more information.

Demo Video

microCMA Sample Survey Data (pdf)

microCMA Sample Data files (CMapp native and ASCII txt)

To view CMapp files, download and install the CMapp application.

ASCII text samples files can be viewed / graphed from any application that can import columnar text, such as Excel.

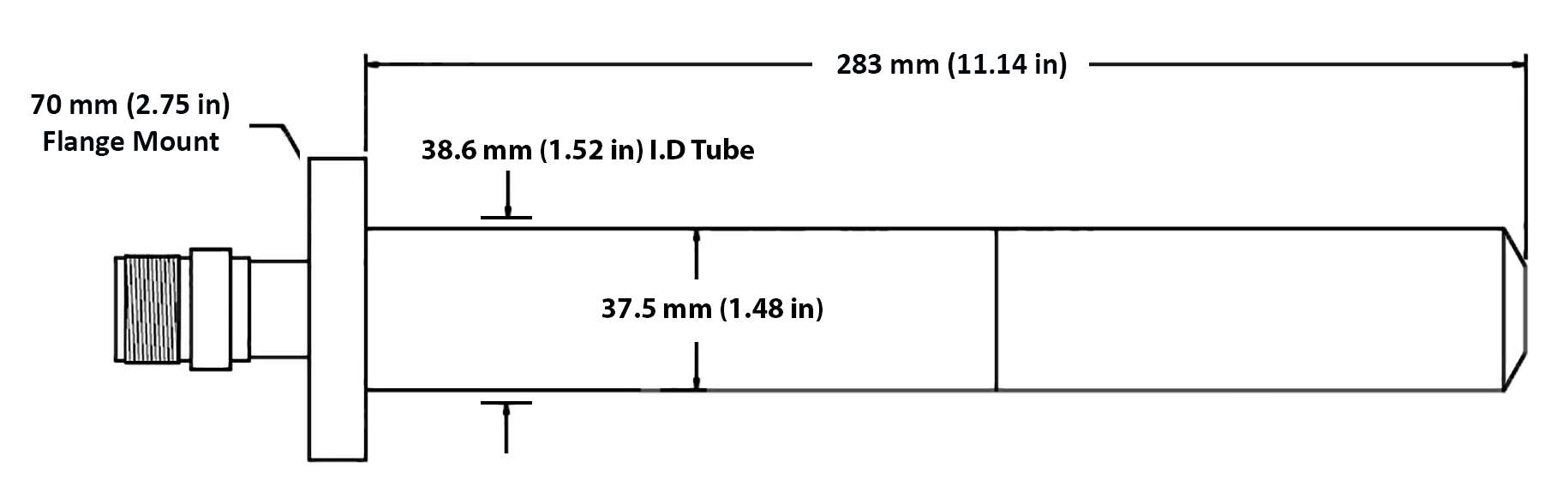

Customs lengths are available. Contact us for more information.

microCMA Dimensions Form

microCMA Dimensions Form (print version)

microCMA Z-Translator Dimensions (STEP files)®

Please fill out this microCMA Dimensions Form indicating the flange-to-sample distance so that we can quote the correct length CMA and Z translator combination.

Customs lengths are available.

| Part Number | Description |

|---|---|

| MCMAPR | microCMA package: Controller, Analyzer & System Cable. Includes Compact 2.75" / 70 mm CF flange mounted Auger CMA with USB control, software and cables. Z-translator and 9103 picoammeter are not included in price. Z-translator is required. 9103 is recommended. |

| EQA-BLT27S-02 | Z axis translator, 2" (50mm) stroke, Compressed Height 2.6" (66mm) |

| EQA-BLT27S-03 | Z axis translator, 3" (75mm) stroke, Compressed Height 2.75" (70mm) |

| EQA-BLT27S-04 | Z axis translator, 4" (100mm) stroke, Compressed Height 2.9" (74mm) |

| EQA-BLT27S-06 | Z axis translator, 6" (150mm) stroke, Compressed Height 3.2" (81mm) |

| MCMACTLRPR | microCMA Controller Only |

| MCMAOPPR | microCMA Analyzer Only |

| MCMA-5901-EDR | Channeltron CEM 5901 Multiplier for mCMA, EDR |

| MCMA-CA17-A | microCMA System Main Cable - 15-foot (4.6-meter) length |

| MCMA-CA17-B | microCMA System Main Cable - 10-meter (32.8-foot) length |

| MCMA-CA17-U | microCMA System Main Cable upgrade to 10-meter (32.8-foot) length when purchased with MCMA Package. Incurs additional charge. |

microCMA Drivers

Unplug the microCMA USB interface before downloading, then plug back in for updates to take effect.

CMapp for the microCMA - Version 1.3

In regions such as China without access to YouTube, the training videos can also be found here.