Ideal for large O-ring sealed vacuum systems and load locks, the UVB-100 is designed to desorb water vapor and remove oxidative hydrocarbon in high and ultra-high vacuum chambers, the UVB-100 Water Desorption System utilizes UV radiation to desorb layers of water vapor without the intense heat of IR or a radiant bakeout.

For surface analysis systems, using a UVB-100 means that you can load samples more quickly and without introducing water vapor into your system. For high vacuum systems, faster pump-down times mean more process runs and higher productivity.

In production systems, the UVB-100 provides faster ultimate pressure and quicker removal of desorbed water during pumpdown.

For added safety when using the UVB-100, a handheld, the easy-to-use battery-powered UV-C Meter is available as an optional purchase.

Base package: UVB-100 controller (90 to 264 VAC input voltage), emitter mounted on 2.75” (70mm) CF flange, 15 ft (4.6m) cables and manual.

Optional accessories: Additional emitter with cables, 40KF mounting flange on emitter, remote turn on relay option (voltages 12, 24, 120, 240 AC and 12,24,48,100V DC are available), custom length cables (up to 30 ft (9.14m).

Complete configuration and ordering information...

Demo Units Available

Not sure if the UVB-100 will work for your application? Contact us for more information about our rental program. For a nominal rental charge, you can try a UVB-100 package for 30 days and see if you get the desired results. If so and you decide to purchase the package, then the rental fee is applied to the purchase price.

Please read this FAQ for additional information.

When returning a demo UVB-100 package to RBD that has been installed in a vacuum chamber please fill out this Non-Contamination Form and return it with the UVB-100 package.

Emitter Options

Flange Mounting:

2.75 CF (top) or NW40 (K150) KF (bottom) - (other flange mounts are available on request)

Technical Information

Theory of Operation

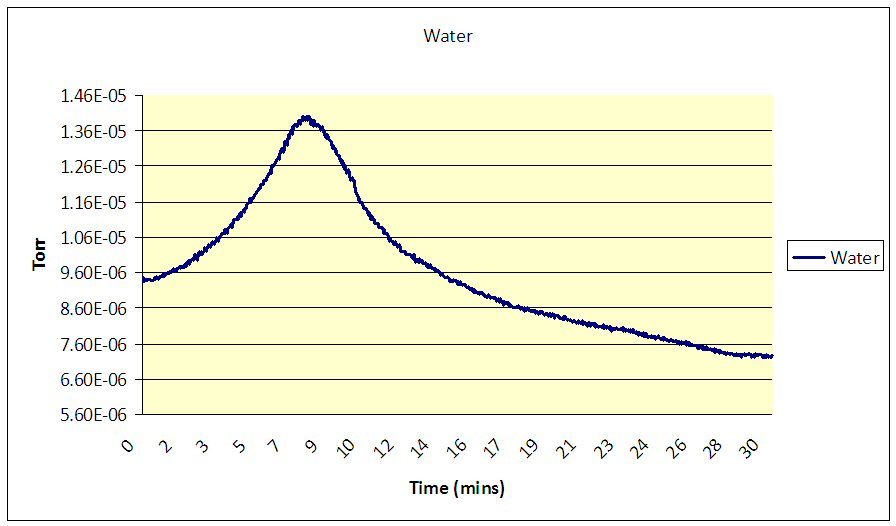

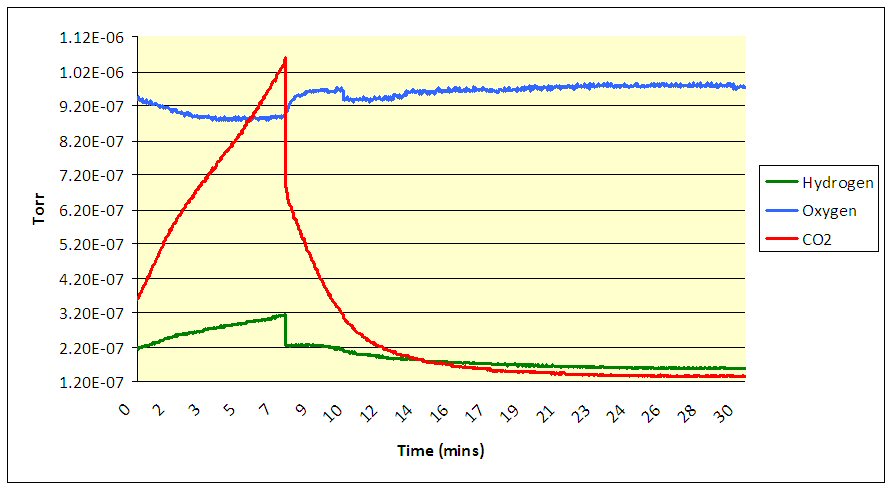

Layers of water vapor molecules on the inside of vacuum chambers can be desorbed by energizing them with ultra-violet radiation in the range of 190 to 200nm, which provides sufficient energy to break covalent bonds. The graphs below show the effect of UV energy on water, hydrogen, oxygen and CO2. In this case, the UV emitter was activated for 8 minutes and then turned off. You can see from the graphs that the water vapor desorption rate increased during the UV ON time and then dropped off significantly when the UV was turned OFF.

The second graph shows an increase in H and a significant increase in CO2 as well as a reduction in oxygen during the UV ON time and a corresponding decrease in CO2 and H when the UV was turned OFF. The CO2 will vary with the amount of hydrocarbon available for reaction with O free radicals and O3.

Application Notes and Whitepapers

UVB-100

The Vacuum Chronicles

For more information on water vapor and it's effects on vacuum chambers, the following application notes are modified versions of various editions of The Vacuum Chronicles, originally published by Phil Danielson - inventor of the Phototron, the design of which the UVB-100 is based. (His complete library of articles can be found here.)

- UVB-100: How It Works (pdf)

- UVB-100: Residual Gas Composition (pdf)

- UVB-100: UV Enhanced Deposition Part 1 (pdf)

- UVB-100: UV Enhanced Deposition Part 2 (pdf)

- UVB-100: Water Desorption Pressure Relationship (pdf)

All of Phil Danielson's vacuum articles can be found here.

Download the full collection of the Vacuum Chronicles

| Part Number | Description |

|---|---|

| UVB100PKGPR | Includes UVB-100 controller, one emitter mounted on a 2.75"/ 70mm flange (specify 2.75" CF or KF-40 flange), 15 ft. / 4.6m cable set, and power cord. Universal input voltage is 100VAC to 240VAC. |

| UVB100-CTLPR | UVB-100 Control Unit (Output cable set not included; UVB100-CA1-SHV or UVB100-CA1-CSTM would be required) |

| UVB100-EMIPR | UVB-100 Emitter Assembly- Specify 2.75" / 70mm CF or KF-40 Flange. Specify 2.75" CF or KF-40 flange (Output cable set not included) |

| UVB100-CA1-SHV | UVB100 SHV/SHV Control Cable, Set of 2, 15 feet/ 4.6m, from Controller to Lamp Assembly |

| UVB100-CA1-CSTM | Control Cable Set, UVB100 SHV to SHV, from Controller to Lamp Assembly. Custom length per customer request, up to 10m. Incurs additional charge based on length. |

| UVB100-CA1-CSTM-U | Custom Length Control Cable, Set for UVB100 when purchased with full package, up to 10m. Incurs additional charge based on length. |

| UVBLAMPPR | UVB-100 UV Emitter w/couplers (flange not included) |

| UVB100-RemotePR | UVB-100 Remote Option; Specify remote Input:12, 24, 120, 240 VAC; 12, 24, 48, 100 VDC |

| UVB100 Demo | UVB-100 Water Desorption Unit with Emitter (specify 2.75" CF or KF-40 Flange) and UVC Meter. Monthly rental. Rental fees are applied to purchase price. |

| UVB100 Demo Extra Emitter | UVB-100 Emitter Assembly. Specify 2.75" CF or KF-40 Flange. Includes SHV Cable. Monthly rental. Rental fees are applied to purchase price. |

Support

Manual - includes important safety information

UVB-100 SOLIDWORKS®

UVB-100 Lamp Assembly

UVB-100 Emitter Spectrum